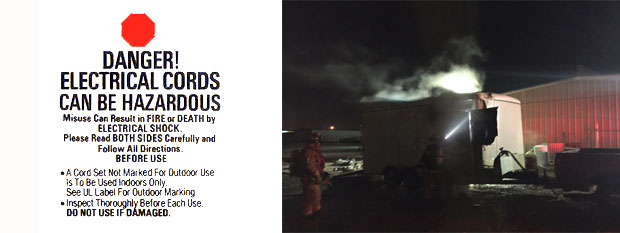

Extension cords are designed to deliver electrical power where it is needed. They should be used only when fixed wiring is not feasible. These common devices are subject to misuse and abuse, too often with disastrous consequences. Misuse can lead to fires and personal injuries and result in thousands of dollars of destruction. Selecting the proper cords and using them safely is worth the effort.

It is not uncommon for individuals to purchase the first power cord they see. Extension cords often look similar, but each type is designed for a specific type of job. In order to select the right extension cord, it is important to become familiar with a few terms.

- VOLTAGE - (V) The difference in charge between two points

- WATTS - (W) A unit of power or the rate at which electrical energy is dissipated

- AMPERES - (A) A unit of measure of the rate of electrical flow or current in an electrical conductor

- RESISTANCE - (r) A material's opposition to the flow of electric current; measured in ohms

- CURRENT - (I) The amount of charge flowing through a circuit or wire; measured in Amps

- GAUGE CAPACITY; Identifies the type of electric cord

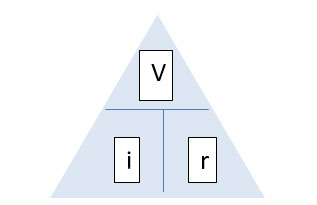

While you may never need to use the following calculations, they are included here for those who do. Simply cover the item you wish to calculate and do the math. No algebra is required. Calculating the Voltage, Current, and Resistance: Ohm's Law Made Easy.

- CURRENT - (i) To calculate the current (i), divide the voltage by the resistance.

- VOLTAGE - (V) To calculate voltage (V), multiply the current (i) by the resistance (r).

- RESISTANCE - (r) To calculate resistance (r), divide the voltage by the current.

Two factors can help determine which cord should be used for a given situation: Length and thickness. In general, the ticker the wire, the more electricity it can handle. Electrical transmission diminishes with distance, i.e., the longer the distance, the less effective the power. Longer extension cords require a heavier wire to deliver a full current.

There are two types of electrical cord construction: The first is "S" stands for "hard service" and the second is "SJ" stands for "Service Junior" or "Junior Service". The Junior Service (JS) is made for a lighter duty and is less rugged than the hard service "S". Additional letters indicate the performance characteristics of the cord.

The thickness of the wire can be identified by the letters AWG followed by numbers, such as 12, 14, or 16 which are printed on the wire jacket. Keep in mind that less is more-- the lower the number, the thicker the wire. Heavyweight AWG 12 should be used for the most demanding operations.

T: Thermoplastic insulation, instead of a rubber-type material

E: Thermoplastic elastomer insulation (more rubber-like or pliable than thermoplastic).

O: Oil resistant

W: Moisture and sunlight resistant

Some of the following are multiple-letters combinations, such as SJT or SJTOW or SEOW. Other markings include the maximum voltage for which the cord may be used along with and the markings of a certifying lab such as UL. These letters appear either on the cord or its packaging. The lettering that usually follows the wire gauge identifies the type of cord which describes its physical construction.

T: Thermoplastic insulation, instead of a rubber-type material

E: Thermoplastic elastomer insulation (more rubberlike than thermoplastic).

O: Oil resistant

W: Moisture and sunlight resistant

The following are some simple rules to follow:

- Extension cords should only be used as a temporary solution.

- Make sure cords are rated for their intended use.

- Inspect cords for wear and tear.

- Check for frayed sockets, cracks, loose connections, and bare wires

- Never use a cord that feels hot

- Do not run cords through walls and ceilings. This can cause over-heating.

- Never nail or staple an extension cord to hold it in place.

- -Make sure the cord is not pinched in doors, windows, etc.

- Keep extension cord out of the way of high traffic areas.

- Insert plugs fully, making sure no that part of the prong is exposed.

- Make sure the extension cord is certified by a nationally recognized testing laboratory, such as UL, CSA, or ETL, and read the manufacturer's instructions.

Extension cords are relatively low cost compared to the expense of replacing a ruined tool or equipment. A cord that can handle a higher electrical current is never too big to use for a smaller job. But, using a cord designed for a smaller job, on a high demand need, can wreck your day.