Custom spray foam rig builders must consider the weight and placement of all the equipment and materials to ensure proper load distribution during travel. The type of spray foam machine used, the generator, and compressor power requirements will determine the over-all trailers size and weight considerations that affect the spray foam rig's overall stability during motion. Spray rig trailers typically are built using 10,000, 14,000 and 16,000Lb GVW (gross vehicle weight options). Leaf spring and torsion axels are two options.

See:(Trailers for Custom and Mobile Spray Foam Rigs ).

Air-driven spray foam equipment will need more CFM (cubic feet per minute) of air to operate the machine, which means that the air compressor size and weight must be large enough to accommodate the air needed for all of the components. Hydraulic driven spray foam machines, equipped with a horizontal proportioner pump line, will require a larger generator.

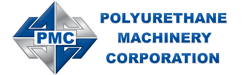

There are 4 power supply options: 220 Volt shore power, gas generators, diesel generators and diesel generator compressor combo units. Direct access to a power supply at the job site, also called shore power, requires a 220 Volt power supply or contractors can rent a portable generator for the project.

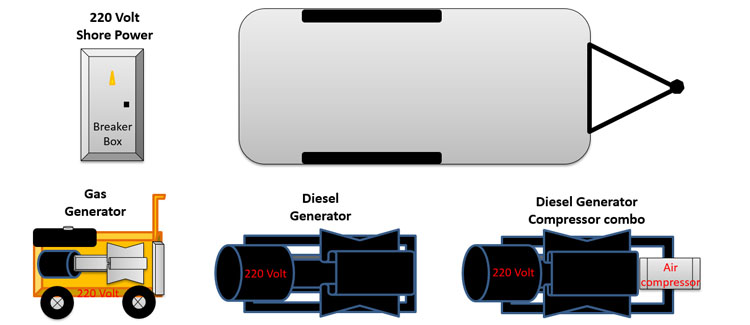

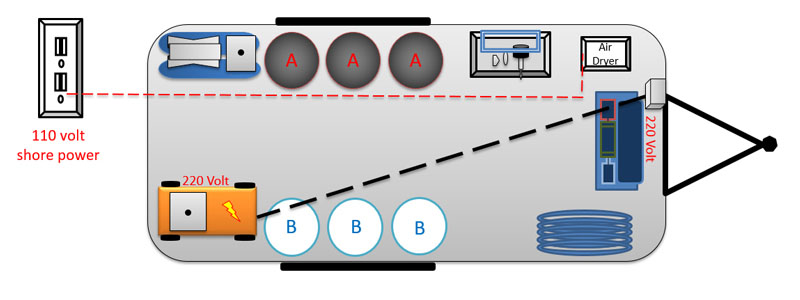

Example of a Shore Power Set-Up

The following shows a 16 foot V-Nose 10,000 GVW shore power spray foam trailer. The rig gets its 220 volt power by being connected to a 220 volt breaker box from the home or building, which is then connected to the breaker box inside the trailer. This connection is typically performed by a certified electrician or authorized maintenance personnel. The 220 volt power is usually routed throughout the trailer. The spray rig's breaker box also contains an option for using 110 volt power for equipment that only requires 110 volts, such as lights, drum heaters, and fresh air supply systems.

16ft V-Nose 10,000 GVW Shore Power Spray Foam Trailer

Gas generator-powered mobile spray rigs and trailers typically have enough power to accommodate smaller spray foam machines; however, they are unable to provide enough power for other equipment, such as drum heaters, AC units, refrigerated air dryers, electric compressors and job site related tools. It is also common to see a spray rig set-up with a gas generator accompanied by a gas compressor and a 110 Volt shore power, which reduces the spray rig's power requirements and power consumption.

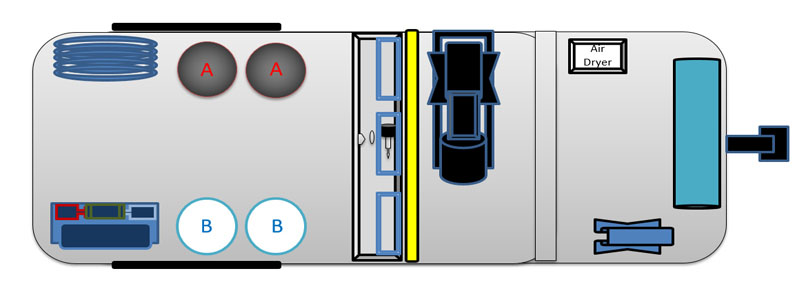

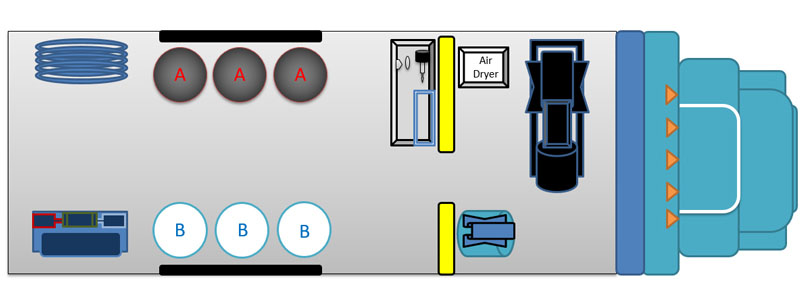

Example of a 16ft Mobile Spray Foam Rig with 110 Volt Shore Power

| 1 - 16 ft Trailer | 5 - Gas Generator | 9 - Gas-Air Compressor |

| 2 - Heated Hoses | 6 - Material Storage | 10 - Tool Box |

| 3 - Cabinets | 7 - Work Bench | 11 - Air Dryer |

| 4 - Spray Foam Machine | 8 - Spray Guns | 12 - Transfer Pumps |

Diesel powered mobile spray foam rigs can be set up to power smaller or larger spray foam machines. The larger the machine, the more power it will require; therefore, a bigger trailer and or box truck will be needed to support the added weight of the equipment. Larger spray foam rigs, with big spray foam machines, typically require a 30 KW generator and up. This will ensure an adequate power supply to the machine and other key components within the trailer including the fresh air supply systems, power tools and other job site equipment.

Example of a 24ft Diesel Powered Gooseneck Mobile Spray Foam Insulation Trailer

| 1 - 24 ft Gooseneck Trailer | 5 - Diesel Generator | 9 - Elec-Air Compressor |

| 2 - Heated Hoses | 6 - Material Storage | 10 - Tool Box |

| 3 - Cabinets | 7 - Work Bench | 11 - Air Dryer |

| 4 - Spray Foam Machine | 8 - Spray Guns | 12 - Transfer Pumps |

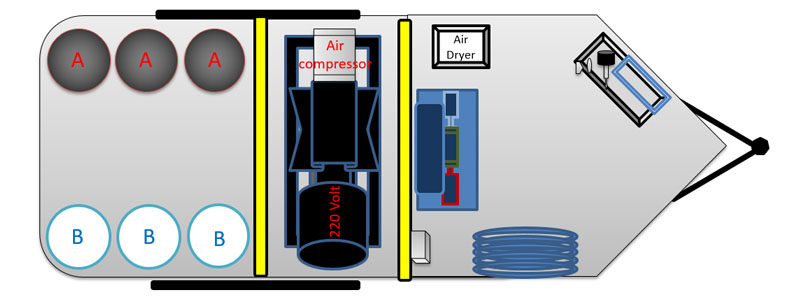

A Diesel generator compressor combo unit provides 220 volt power and an air supply to the spray foam rig and spray foam equipment components from one source. Custom mobile spray foam rig manufactures can customize a variety of space-saving smaller and larger spray machines, trailers, and box trucks configurations.

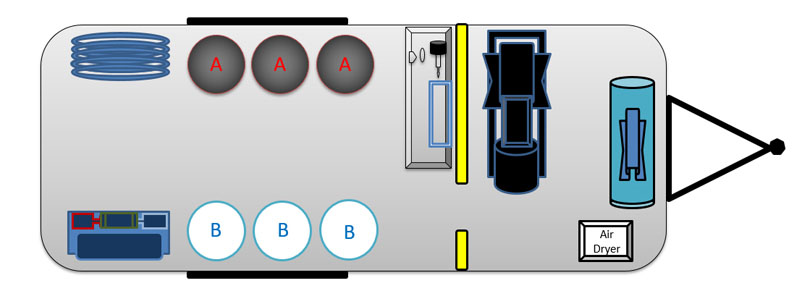

Example of a 16ft V-Nose Diesel Generator Compressor Combo Mobile Spray Foam Rig

| 1 - 16 ft V-Nose Trailer | 5 - Diesel Generator | 9 - Breaker Box |

| 2 - Heated Hoses | 6 - Material Storage | 10 - Tool Box |

| 3 - Cabinets | 7 - Work Bench | 11 - Air Dryer |

| 4 - Spray Foam Machine | 8 - Spray Guns | 12 - Transfer Pumps |

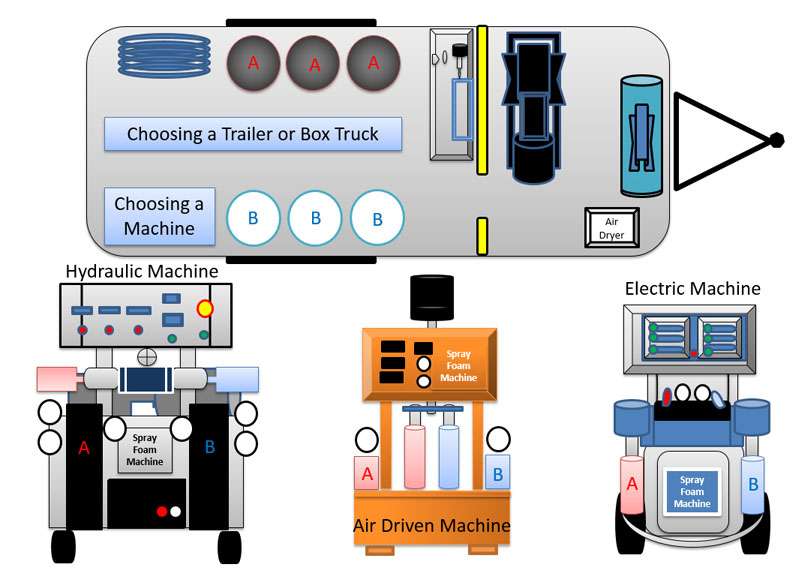

Choosing the right spray foam machine can be a daunting task. Spray foam machines or reactors come in different sizes, colors, drive systems, weight and power requirements. In general, air driven spray foam machines do not require as much electrical power as electric, hydraulic, or combination spray foam machine. The drive system, pre-heater(s), the length of heated hose, and a machine's ability is to heat the hose(s) also plays a major roll in the deciding power requirements. Moreover, single and three-phase power options are available on most spray foam machines as well as electric compressors. Another consideration is that single-phase power machines draw more amps than three-phase machines. Learn what all spray foam machines have in common.

All of the above information impacts the design of a spray foam trailer or box truck. The spray rig components should also be positioned to allow proper maintenance, so contractors can preform regular equipment inspections and service. Since equipment maintenance is an on-going process, the spray rig's mechanic's station should be easily accessible to work on spray foam guns and other equipment as needed.

Other regular maintenance and inspections cycles should be preformed include materials, drum pumps, filters, screens, O-Rings, hoses, lube reservoirs, and or exposed piston shaft yoke areas. A well-trained spray foam contractor can keep his spray foam rig equipment maintained, organized, and operational in about one hours time.

Example of a 24ft Spray Foam Box Truck With Diesel Generator

| 1 - 24 ft Box Truck | 5 - Diesel Generator | 9 - Elec-Air Compressor |

| 2 - Heated Hoses | 6 - Material Storage | 10 - Tool Box |

| 3 - Cabinets | 7 - Work Bench | 11 - Air Dryer |

| 4 - Spray Foam Machine | 8 - Spray Guns | 12 - Transfer Pumps |

Spray foam contractors should carefully assess their project needs and budget limitations. It is important to consider your company's growth potential in order to obtain equipment that can grow with the company's needs. He or she should be able to ask important questions before committing to the purchase of spray foam equipment and/or a spray foam rig. A qualified spray foam equipment distributor should be able to assist you with all of your questions.

Below are examples of all major types of custom mobile spray foam rigs designs:

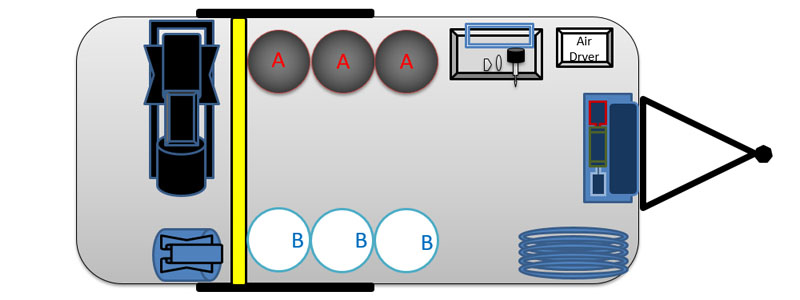

Example of a 20ft 14,000Lb GVW Spray Foam Rig with Diesel Generator

| 1 - 20 ft Trailer | 5 - Diesel Generator | 9 - Elec-Air Compressor |

| 2 - Heated Hoses | 6 - Material Storage | 10 - Tool Box |

| 3 - Cabinets | 7 - Work Bench | 11 - Air Dryer |

| 4 - Spray Foam Machine | 8 - Spray Guns | 12 - Transfer Pumps |

20ft Spray Foam Trailer with Diesel Generator

| 1 - 20 ft Trailer | 5 - Diesel Generator | 9 - Elec-Air Compressor |

| 2 - Heated Hoses | 6 - Material Storage | 10 - Tool Box |

| 3 - Cabinets | 7 - Work Bench | 11 - Air Dryer |

| 4 - Spray Foam Machine | 8 - Spray Guns | 12 - Transfer Pumps |

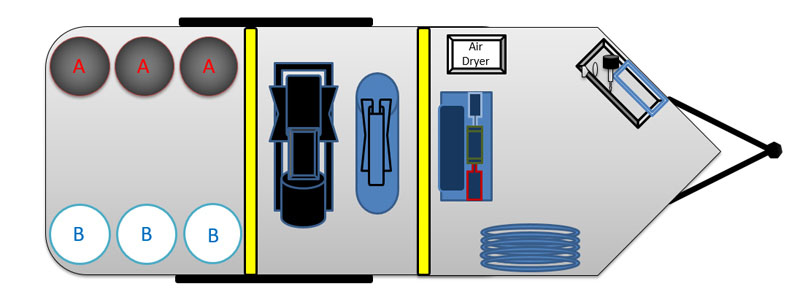

20ft V-Nose Spray Foam Rig With Diesel Generator and Electric Compressor

| 1 - 20 ft Trailer | 5 - Diesel Generator | 9 - Elec-Air Compressor |

| 2 - Heated Hoses | 6 - Material Storage | 10 - Tool Box |

| 3 - Cabinets | 7 - Work Bench | 11 - Air Dryer |

| 4 - Spray Foam Machine | 8 - Spray Guns | 12 - Transfer Pumps |